Fixturlaser EVO – Laser optical instrument for Express Alignment

Simplicity in your hands The laser-based shaft alignment tool, EVO, is all about evolved simplicity.

It is a product without the frills and the bling, bling that stays true to our core values: simplicity, user-friendliness, and innovative techniques, while at the same giving you the power of alignment in your hands. The EVO offers a compact display unit with a 5” color touch screen. It is slim and balanced, allowing you to hold it in one hand, leaving your other hand free to touch the screen icons and rotate the shafts.

It has a clean and color-coded graphic user interface that helps the maintenance professional throughout the measurement and alignment process without any hassles and stress.

The EVO offers an extensive shaft alignment package, including the Feetlock function that is useful in base/bolt-bound machine situations.

Fixturlaser NXA Pro – Ultimate Measurement Tool for Optimal Operation Conditions

Fixturlaser NXA ProWith the Fixturlaser NXA Pro you have covered any kind of angle that needs

to be covered of your machinery. It includes shaft alignment applications as well as

geometric applications, hence, as the name says, it is an ultimate measurement tool. Latest Technology for Fast and Intuitive Handling The Fixturlaser NXA Pro utilizes the latest technology in both the display unit

and in the sensor units. We have implemented new technology by using CCD, digital

signal processing, a 3D animated and adaptive graphical user interface, as well

as other innovations, to provide the users with an even faster and intuitive measurement

and alignment process. Ultimate Measurement Tool for Optimal Operation Conditions With a mix of shaft alignment and geometry applications, you are safeguarding your

machinery’s operation condition. Regular maintenance checks or installations of new

machinery, you have what you need in the Fixturlaser NXA Pro. Machine foundations

need to be checked for any flatness faults, before the machine is actually

installed, hence the flatness application. And once installed, the machine’s alignment

status must be measured. With everything verified to be perfectly aligned, you can

also ensure the machinery’s optimal operation conditions. Green Benefits The benefits of precision shaft alignment (reduced vibration levels, less wear on

bearings and mechanical seals, and lower power consumption) and correctly

installed machinery will result in lower operating costs, not to mention fewer unplanned

stoppages.

By minimizing wear, production stoppages and costs, you will also

contribute to a more sustainable environment!

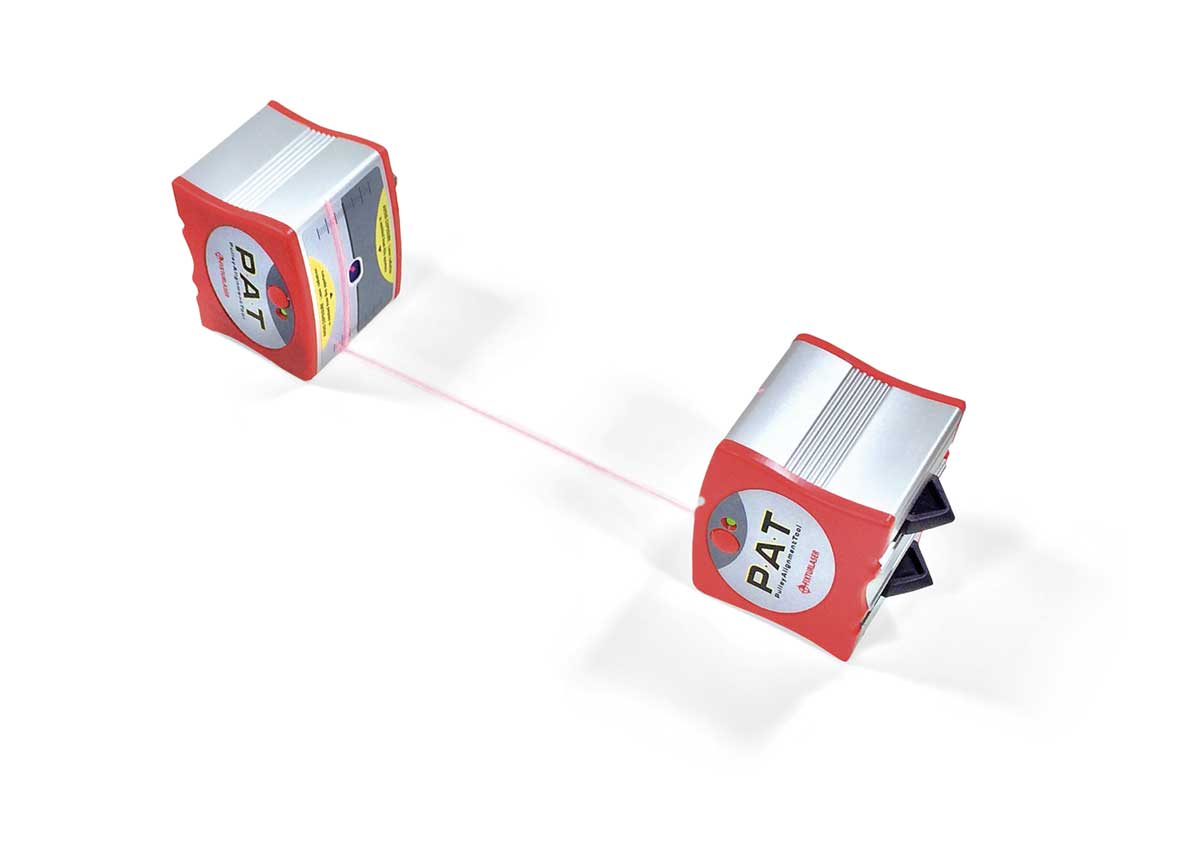

Fixturlaser PAT – Belt drive alignment

PAT – the final solution to all your belt alignment needs! With the PAT, you are never in doubt about whether your belt transmissions are aligned or not. By using the groove as reference, you will achieve a precise alignment which reduces belt wear, bearing failures and vibrations.

Two transmitters with visible red laser lineThe PAT comes with two-line laser transmitters, each equipped with two spring-loaded guides that fit into the pulley grooves. The use of two laser transmitters with integrated targets makes it very easy to find out what kind of alignment is required. Parallel offset, angular error, and twist are instantly visible to the operator. Within a few minutes, the operator can determine if the machine requires alignment or not.